NAMI Public Furniture

If you read my previous blog about Assignment 2, you will know what I did just to avoid my lecturer from choosing my design... And what happened next? My design got chosen! I'm needed to build the furniture out with my teammates, Shania and Men Ping. I was so sorry to them that they are picked to be in my group - the tsunami group. They have to suffer with me in building this wavy thing out... So, what's next? Building material? Redesign? Money? My mind was totally blank when my lecturer told me that she was hoping to see my prototype... Okay... Challenge accepted T.T

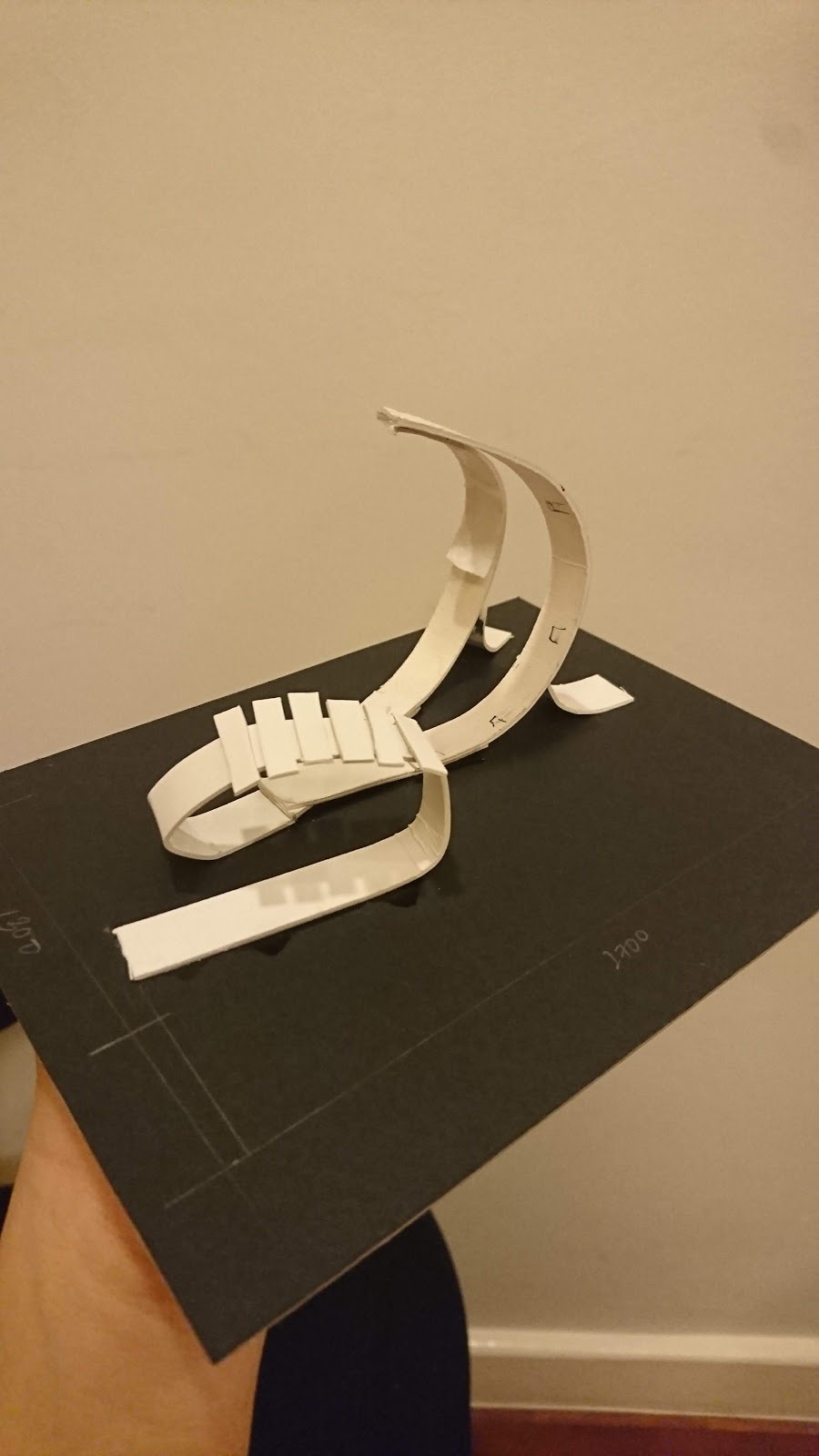

First step first, we simplify the design to a more clearer form. Therefore, we reduce the strips used yet maintain the curve structure and we added a bench to balance the whole form. It looks balanced and seems more easier to make it.

|

| First simplified mock up |

But, we feel like the latest design is more like two different pieces assemble together. It loses the flow in it, so we did another mock up and started to figure out more detailing part such as material used, assembly method etc. My lecturer also suggest that we should use bendable plywood for our furniture. So, we went to some hardware shop and ask some advice from the owner. The uncle from wood hardware shop is helpful. He suggest us to do a steel structure so that the bendable plywood can be screw on it and stay in shape. And lucky me, I know a steel factory due to my past assignment in IAD 2. We are so lucky to have a steel construction worker that is so committed in building student furniture. He gave us a lot of advice and idea so that we can work smoothly when we assembly the wood planks ourselves. He also gave us discount on the steel structure, from original price RM 1000 to RM600.

|

| Finalised Mock up |

|

| Stage 1 steel structure (curve part) |

|

Stage 2 steel structure (whole structure)

*I forgotten to snap stage 3 which is coated with black paint* |

|

| Making a hole when it is hard to screw |

|

| Screwing self drilling screw to the steel structure |

|

| At first, we thought we can do one plank for the whole strips, but it can't work. So, we did it piece by piece. |

|

| Initially, this wood on the bench should be horizontal place, but we feel that one piece is nicer so here it goes! |

|

Coating with shellac. Actually I prefer the natural colour of plywood, but without finishes, this furniture is not complete.

*After done, I only know that there's other finishes...* |

|

| My naughty doggies just cant leave the furniture alone. |

Last but not least, I would like to thanks everyone who helped me in this project. My teammates, Men Ping & Shania, thank you for tolerating me and helping out each other as a team. I will say that this group is a very productive team! Giving me a lot of help. Secondly, thank you Ms Sim, my lecturer! She is a product designer and part-time lecturer at the same time. She gave us a lot feedbacks on every tutorial no matter in the term of design or material used, even assembly joints. She is very committed in teaching all of us and always encourage us to participate in competition. She fights for what is right and backing us up. Also, I would like to thank all the uncles that advice me when I was so blur in production making. I'm so grateful that I met the uncle that willingly to teach me things as a beginner. Lastly, shout out a big thank you to my friend, Brinn that drove my furniture to and fro from my house! Without his Isuzu, I don't think we can even put on the plywood on the steel structure! Even though this module stress me out a lot, but I gain lots of experience in production making and real life problems. Shout out to the world! I'm still surviving! HAHAH

|

| Final Presentation with my teammates, Men Ping & Shania |

|

| Presentation Board |

Wood Hardware Shop: Fung Sang Furniture Hardware

No. 109 & 110, Jln Besar Ampang, Ampeng, 68000, Ampang Selangor.

03-4297 3776

Steel Factory: No Name (It is near the Petron Safari MRR2)

Encik Hashim: 017-344 8455

0 comments: